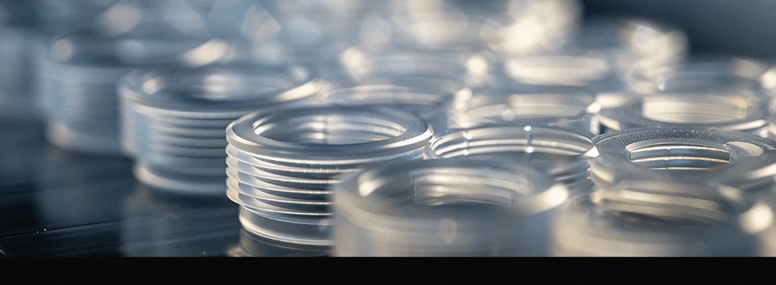

The Benefits of Using Tapered Plastic Plugs for Various Applications

Tapered plastic plugs are crucial for protecting, sealing, or masking components in numerous industrial applications. These plugs offer a versatile and reliable solution, from safeguarding threaded pipes during transportation to paint masking for intricate machinery part finishes. They are designed with ease of use in mind, allowing for simple insertion and removal without the need for specialized equipment. Understanding the full spectrum of their advantages is key to optimizing processes and protecting valuable resources. Keep reading to learn about these tools' various roles in the industry.

Enhanced Protection Offered by Tapered Plastic Plugs

The most apparent benefit of using tapered plastic plugs is the level of protection they provide. These plugs are a barrier against dirt, dust, moisture, and other environmental factors that could damage components during storage or transit. By creating a secure fit within openings, they prevent foreign materials from compromising the function and quality of products.

Tapered plastic plugs are invaluable in surface finishing processes such as painting, powder coating, or anodizing. They precisely mask areas that must remain free from coatings or treatments, ensuring a clean, professional finish. As finishes often determine a product's final appearance and corrosion resistance, this accuracy is crucial for quality control.

Moreover, tapered plastic plugs' impact resistance shields components during handling and transport. The snug fit and durable material composition absorbs shocks and jolts, minimizing the risk of damage from falls or collisions. This protective quality is essential for components that maintain exact engineering tolerances and functionality.

Additionally, tapered plastic plugs' adaptability to accommodate various pressure levels is a testament to their superior design. Whether dealing with pneumatic systems or liquid-filled containers, they can endure under different operational conditions, ensuring a leak-proof seal that upholds the system's integrity.

Versatility Across Industries: Tapered Plastic Plug Applications

Tapered plastic plugs are used in various industries, each with unique requirements and challenges. In the oil and gas sector, they seal off pipes and valves, safeguarding against leaks that could pose significant safety hazards. Meanwhile, the automotive industry protects engine components and fluid lines during manufacturing while vehicles are in transit.

Electronics manufacturers utilize tapered plastic plugs when assembling delicate devices to prevent debris from interrupting the function of intricate circuits. This application underscores the importance of precision in plug design, ensuring that even the smallest ports can be reliably sealed off from potential contaminants.

Furthermore, tapered plastic plugs are also a staple in the aerospace industry. Aircraft manufacturers use them to cover holes, fasteners, and fittings during painting or long-term storage. Given the stringent safety and performance standards required for aerospace components, the necessity to reduce any risk of contamination or damage in this industry cannot be overstated.

Even beyond heavy industry, these plugs are used in commercial goods manufacturing. For instance, the sports equipment, furniture, and toy industries employ tapered plastic plugs to finish products safely and aesthetically. This wide-ranging utility illustrates how these simple devices form the backbone of various production processes.

Customization and Flexibility of Tapered Plastic Plugs

Despite their seemingly straightforward function, tapered plastic plugs offer significant customization options. Manufacturers can produce plugs in various sizes, colors, and materials to meet the specific requirements of different applications. Custom molds can even be created for unique ports, ensuring a perfect fit and optimal protection for any component.

The flexibility of these plugs is further enhanced by the materials used in their construction. Depending on the application, plugs can be made from soft plastics for easy insertion and removal or more rigid materials for added durability. This versatility means industries can tailor the plugs to their precise needs, such as temperature resistance or conductivity.

For scenarios requiring frequent access to ports or openings, specially designed tapered plastic plugs with ergonomically designed handles or tabs can be utilized. They simplify processes that require regular maintenance or inspections, as they can be quickly and efficiently removed and replaced without compromising the seal.

Another aspect of customization that tapered plastic plugs support is adapting to environmental concerns and regulations. Manufacturers increasingly create biodegradable or recyclable options, ensuring companies can maintain environmental stewardship without sacrificing functionality and protection.

Altogether, tapered plastic plugs offer protection, versatility, and customization, making them indispensable across various industries. Ensuring secure seals and precise masking enhances product quality while accommodating specific application needs and environmental considerations.